Low Roughness CNC Medium Wire Cutting Machine HB400X,

※ Best Surface Roughness ≤Ra0.4μm

※ Maximum Efficiency Up To 300mm²/min

※ Nonelectrolyte Power Supply Technology

※HB400X Mechanical Advantages

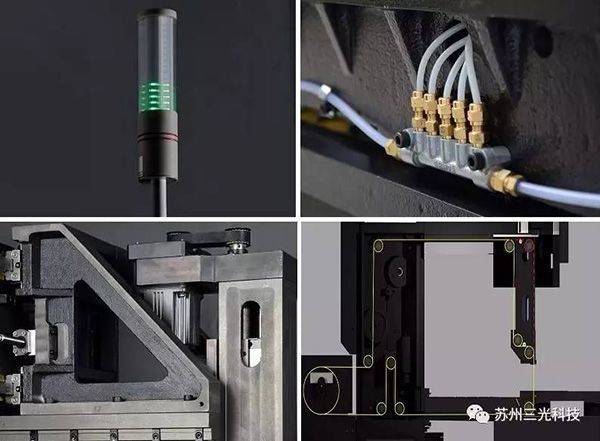

Innovative Framework

Four axes(X,Y,U,V) AC Servo combined with four axes imported ball screw and liner guideway,which guarantee the accurate.

Independent Layout

Independent Layout of X axis and Y axis, With UV…. to ensurance the high accurate. Thick-walled castings with Stiffener configuration avoids the body deformations.

Protect Environment

Frame-shaped water-retaining structure prevents leakage of the cutting fluid in the machining area. The brand-new elevating manager make it more convenient to set work-pieces and greatly saving the space.

LED light

LED light with working indicator light, so you can check the equipment’s running state at any time.

Two ways of wire threading

It meet different machining needs, and helps to change the guider much easier.

Centralized lubrication

Centralized Lubrication for screw of guide rails keeps workshop clean and tidy.

Comfortable Operation

The position can be adjusted randomly so that the operation table can be control easier.

※HB400X Well-designed System

Nonelectrolyte power supply technology

High speed nonelectrolyte power to inhibit electrolytic corrosion, to prevent the formation of "softening layer" and improve the surface quality

Four axes(X,Y,U,V) AC servo control

Imported AC servo system helps cutting speed faster and precision higher

Human-machine interactive system

Copyrighted Windows Platform

Hight-resolution 15in’ large screen display

Technological parameter database

Built-in programming graphics and automatically prepared machining code programs.

The multi-CPU function enables simultaneous processing and programming.

Parallel compensation, clear angle setting, program image, corner optimization, scaling and other functions opened.

Laser ranging calibration and pitch compensation data opening real-time on.

Multiple coordinate system can switch among workpieces rapidly.

Exchange X and Y axis randomly to adapt different machining state.

Set wire controller’s move speed freely.

Record machining tracking information, to monitor machining during unmanned operation to ensure safety.

※HB400X Detect Technology

Test key parts and components by three-coordinate measuring instrument to guarantee the precision.

Ball bar detection to ensure dynamic accuracy.

Geometric accuracy detection to ensure geometric accuracy.

Laser interferometer detection to ensure positioning accuracy

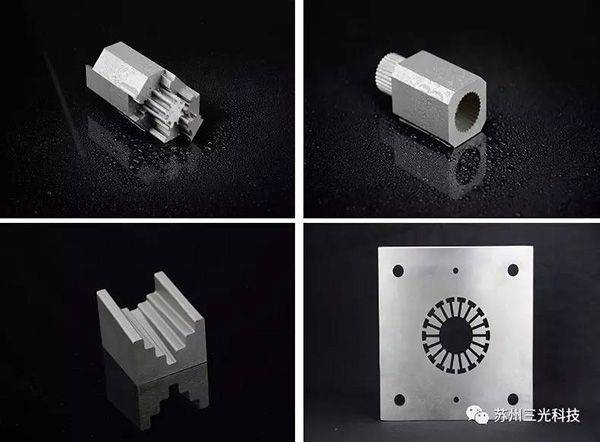

※ HB400X Machining Features

| Punch & Die | Punch & Die |

| Workpiece thickness : 40mm | Workpiece thickness : 60mm |

| Material : SKD61 | Material : SKD11 |

| Best Surface Finish : Ra<0.6μm | Best Surface Finish : Ra<0.8μm |

| Cutting numbers : 4 | Cutting numbers : 4 |

| Tolerance : 5μm | Tapper Angle : ±6º |

Porous Mould processing

Workpiece thickness : 20mm

Workpiece material : Cr12

Best Surface finish : Ra<0.6μm

Pitch Accuracy : <0.009mm

※HB400X Machine Parameters

Machine Body

Worktable stroke(X,Y): 400mm*300mm

Wire Diameter : ∅0.1-0.25mm

Wire Speed : 1.18-11.8m/s

Machine weight : 2260㎏/2560㎏

Machine Dimmension(L*W) : 长2010mm*宽1650mm

Workpiece

Max.workpiece height : 300mm

Max. Cutting Angle : 20º/100mm

Worktable size : 580mm*460mm

Max.workpiece weight : 500㎏

Water tank

Filter accuracy : 0.01mm

Capacity : 130L

Working Methode : Filtration System

Pulse Power

Max cutting speed : ≥300㎜²/㏕

Best Surface Finish : Ra≤0.4μm

Max. Cutting Currrent : 12A

CNC System

Hardware Configurations : ndustrial computer, LED display, Mitsubishi AC servo driver system, Schneider Inverter

Data Port : USB, LAN

Programming Code : ISO code

Axis Numbers : 5-axis and 4 axis simultaneous control, pitch compensation realized.

Menu Language : Chinese/English/English (Inch)/ Italian/ Korean/Japanese

Joy Stick : Standard

Titanium Aolloy Machining : Standard

Z axis Motor : Standard

Aluminum Cutting Device : Standard

Power Supply

Power : 3-380V±10% 50±1HZ

Working temperature : 10-35℃

Consumption : 1.2KVA